Sage X3 manages your entire manufacturing operation faster and more effectively – from procurement and scheduling to shop floor, inventory, sales and financials – and provides better insight on quality and costs to promote strategic collaboration and improved operational efficiency. There are two main type of Sage X3 Manufacturing: Discrete Manufacturing and Processes Manufacturing.

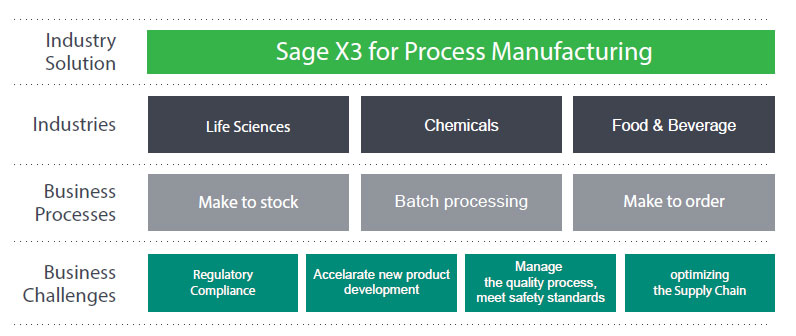

Sage X3 – ERP for Process Manufacturing

Process Manufacturing ERP software solutions

Designed to meet the demands of process manufacturers Sage X3 will improve overall performance of your business and will help to improve your business processes such as your supply chain and product development. It will also manage processes to ensure quality, safety and legal compliance. It will enable you to design and produce new products cost-effectively, and identify and implement best practice.

Sage X3 records every step of production and every transaction. Quality control checks, tolerances, electronic signatures and deliveries can all be enforced and checked. Users can then access this information quickly and easily on the web. This means that you can be sure your production system maintains high quality, are safe and complies with the key regulatory requirements for your market.

Sage X3 ERP improves the development of new products and reduces time to market. By bringing research and development and production closer together through better integration and sharing of information, Sage X3 ensures a smoother transition from design to production and ultimately, to market. The SAGE X3 Platform opening enables to integrate the PLM function through complementary solutions and provides full visibility so you can track changes to new products as well as monitor overall development costs.

By ensuring you have accurate and real-time information about stock, pipelines and deliveries, Sage X3 enables you to run a truly lean business. From purchase request through receipt and then to manufacture and delivery from production, every step is automated through RF barcoding and scanning. The result is a powerful and easy to use system.

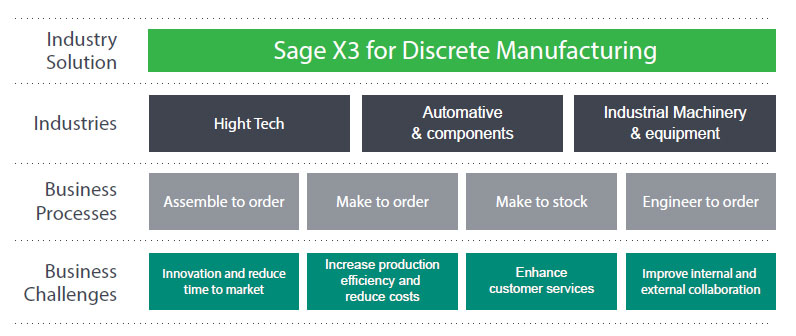

Sage X3 – ERP for Discrete Manufacturing

Discrete ERP software for manufacturing industries

Sage X3 for Discrete Manufacturing will encourage collaboration and innovation to get new products to market quicker. It will make production better and cheaper, improving customer service.

The SAGE X3 platform proposes a dedicated and integrated connector to manage Product Life Cycle Management solution integrating, Bills of Materials (BOM) from Computer Aided Design (CAD) and manages their life cycles. For each new project, you can define and track the tasks, monitor time and manage costs. This improves the new product development process through better collaboration between R&D and production departments.

Real-time control and visibility of production schedules, capacity, shop floor activities and an overview of cost control all contribute to improved productivity. Sage X3ERP is flexible and powerful enough to allow you to switch from make to stock to make to order and mixed order. It also tracks manufacturing processes through the Manufacturing Execution System as Sage ERP X3 provides a dedicated and standard connector to your complementary solutions.

Using the integrated Customer Relationship Manager (CRM) functions, Sage X3 for discrete manufacturers provides a comprehensive view of your customer information. You can quickly determine order status and product availability, for each project, a progress report and financial balance sheet. The CRM function can also manage the after-sales support service with monitoring of equipment delivered to each customer and analysis of all activities.